EASA Part-21G Production Training

If you are an EASA Part-21G approved production organisation, you know that there are a lot of standards for conformity with which you must comply when producing aircraft parts and appliances.

In other words, your production must live up to the strict requirements for airworthiness in everything you do.

We offer several Part-21G training solutions for your production organisation which ensure compliance with airworthiness standards.

Aviation is a field where you do not want to reflect non-compliance.

Looking for a specific course?

Want to sign up for a course?

PRODUCTION ORGANISATION TRAINING

In a Part-21G production organisation, many people with different competencies and job functions intersect every day. That is why we need to be aware of who everyone is and which job everyone is assigned to perform.

Our Production Organisation Training touches upon the different job functions, areas of responsibility, and the interaction with Design Organisations and Part-145 Maintenance Organisations.

We offer both initial and recurrent Production Organisation training.

SMS - Safety Management System

Lack of past problems does not guarantee a safe future! But implementing a Safety Management System into your organisational culture certainly helps. SMS is about identifying bad procedures, hazards, risks, and insufficient barriers. Being aware of the potential dangers in your organisation allows you to make informed decisions to either accept them or do something actively to address the situation.

Our introductory SMS training for managers in Part-145 and Part-21 organisations provides the fundamental knowledge to design and implement a safety management system tailored to your needs. Applying a new safety mindset contributes to a strong safety culture in all layers of your organisation.

In 2022, EASA established a mandatory requirement for Part-145 maintenance organisations to have SMS implemented into their quality system. Similar requirements will apply for Part-21G Production and Part-21J Design. The deadline for compliance expires on December 2, 2024.

HAVE YOU ALREADY IMPLEMENTED A FUNCTIONING SMS?

We provide tailored initial and continuation SMS training for your staff

taking your specific procedures into consideration.

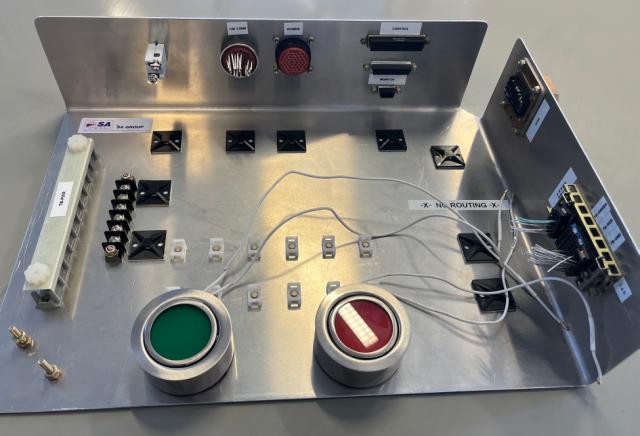

EWIS Module G - Practical Training

EWIS constitutes the lifeline on a plane. If a line is broken, the whole system can potentially collapse.

Our EWIS Module G - Practical Training lays the groundwork for safe and efficient maintenance, alteration, and repair of EWIS in aircraft. The practical dimension enables demonstrations of the proper use of tools when performing repair as well as replacement of connective devices.

We provide initial and recurrent practical training of EWIS Module G – so technicians and mechanical staff performing assemblies and repairs on the system have acquired or maintained the necessary skills to do so.

RECEIVING INSPECTION & SUSPECTED UNAPPROVED PARTS (SUP) TRAINING

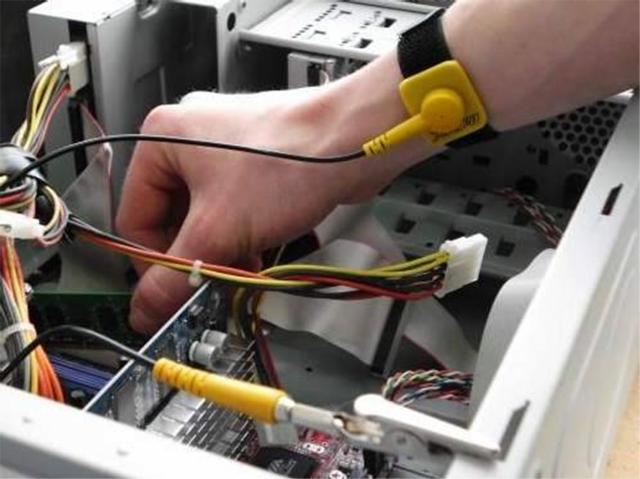

ESD - Electrostatic Sensitive Devices

Electrostatic Sensitive Devices (ESDs) are highly susceptible to damage. Most commonly, damage is caused by human contact.

We offer ESD training which covers both the initial and recurrent training requirements.

We touch upon the following questions: What are ESDs? Why is it important to enhance awareness of these devices? How should you handle ESDs within your organisation? What can you do to prevent damages to ESDs?

FOD - Foreign Object Damage

Foreign Object Damage/Debris (FOD) can cause severe and fatal accidents due to the undetected impact it can have on the aircraft. FOD can potentially originate from many sources. Normal daily operations will produce a lot of this debris with the potential of causing damage to aircraft systems.

Our initial and recurrent FOD training provides an insight into the area of FOD and touches upon the following questions: What is FOD? Why is awareness of FOD important? How can your staff prevent FOD in the operational environment? And how can your organisation support this?

Component Maintenance Training

Aircraft technicians have many different jobs to complete when performing maintenance. One of them is working on detached aircraft components. For this job, a certain knowledge of component maintenance is required to identify the tasks that must be performed for a given component. Everything must be done according to regulations.

Our training in component maintenance is aimed at Component Certifying Staff not qualified in accordance with Annex III. Our training also applies where the qualifications are determined by company procedures and under the approval of the local Competent Authority.

The training will be tailored to fit your needs. We offer training which covers both the initial staff training standard and the specific component maintenance requirements.